Issues related to the power supply for electricity consumers are relevant in any construction, whether it’s the construction of new industrial facilities, the reconstruction of existing ones, or the building of a country house. The quality of electrical installation design impacts the following:

- Compliance with the technological equipment and the requirements for the future facility;

- Operational characteristics that prevent power supply interruptions and reduce the likelihood of emergencies;

- The presence of errors or deficiencies that could negatively affect the subsequent installation of electrical equipment;

- In short, everything referred to as the reliability of the power supply. This is especially important in the case of power supply design for industrial enterprises, where design errors can lead to not only financial losses but also more serious consequences.

What electrical supply projects are and the stages of design

The power supply project is developed according to the requirements of the Unified System of Design Documentation (ESKD) and a series of regulatory documents, presented by state standards, codes of practice, and instructions from guiding documents. The technical documentation set of a power supply project includes both textual and graphical parts.

The textual part includes:

- Descriptions of the characteristics of electrical receivers and power supply sources;

- Justifications for the accepted power supply schemes, including the layout of distribution devices;

- Required calculations, including calculations of electrical power for the receivers;

- Requirements for the quality of electricity and the reliability of the power supply;

- Discussions on protection, control, automation, dispatching, reactive power compensation, etc., as well as grounding and lightning protection;

- Descriptions of systems related to electrical lighting (working and emergency), backup and additional power, and many others.

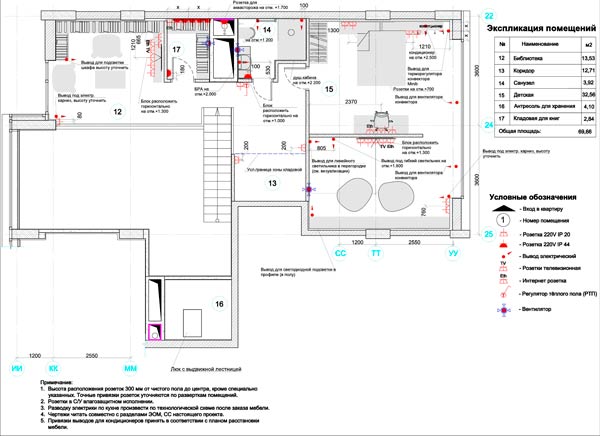

The graphical part of the technical documentation usually includes:

- Plans showing the electrical network of the power supply;

- Diagrams showing the placement of electrical receivers;

- Schemes for organizing protective grounding (neutralization), lightning protection;

- Sets of wiring diagrams for equipment powered from primary, additional, and backup sources;

- Wiring diagrams for the lighting network and emergency lighting.

For example, the graphical part of a power supply project for a city apartment may include a single-line diagram, a lighting scheme, and a plan for placing electrical outlets. For private houses and cottages, external electrical network diagrams are added.

In practice, the design process consists of the following main stages:

- Obtaining Technical Conditions (TCs): TCs are issued by the power supply organization and outline the main requirements for the future electricity consumer, the allocated power, the number of phases, issues of automatic protection, and the project approval process. Essentially, TCs serve as a plan for future design work.

- Preparing the Technical Assignment (TA): This is developed with the direct involvement of the customer and serves as the basis for the design. Essentially, the TA is a draft version of the future project, and it requires an architectural plan and a document outlining the delineation of responsibilities.

- Designing: At this stage, necessary calculations are carried out, wiring diagrams are created, and plans for the placement of electrical equipment are developed.

- Project Approval: The final stage is the approval of the project with the electricity supplier and the relevant regulatory authority.

Considering the high demands placed on power supply projects and the potential consequences of poorly designed systems during the operation of electrical installations, the development of project documentation should be entrusted to specialized design organizations licensed to perform such activities.